Confined Space Resources

Print Materials: Confined Space Safety

Confined Space Safety: Grain Storage Structures Poster

Dimensions: 11×17

This poster outlines essential safety procedures for entering grain storage structures, emphasizing thorough preparation, hazard assessment, and continuous oversight. Before entering a grain bin, workers must clearly define the task and consider safer alternatives. Proper preparation includes assembling the required tools, personal protective equipment (PPE), and designating a trained entrant and observer. A completed and signed entry permit or safety checklist is mandatory. Entry is only allowed when all pre-entry steps are followed, the observer stays outside with constant visual and verbal communication with the entrant, and is equipped to call 911 if needed.

To ensure safety, all grain handling equipment and power sources must be completely shut off, locked out, and tagged out. Air quality must be tested before and during entry—oxygen levels must remain between 19.5% and 23.5%, carbon monoxide must not exceed 25 ppm, hydrogen sulfide must be undetectable, and dust levels must allow at least five feet of visibility. Structural safety is also critical; if grain is bridged, uneven, or if walls or the floor slope inward, a body harness properly secured to the structure is required.

Confined Space Safety: Grain Storage Structures Flyer

Dimesions: 8.5×11

A flyer/handout version of the Confined Space Safety: Grain Storage Structures Poster. This flyer can be used in the field when discussing safety in and around grain storage structures with agricultural workers. It can also be used in the classroom as a teaching aid, summarizing key points for safe entry into grain storage structures.

Confined Space Safety: Manure Storage Poster

Dimensions: 11×17

This poster provides vital safety procedures for entering manure storage structures, emphasizing the importance of thorough risk assessment and strict adherence to safety protocols before entry. Entry is only allowed after the task is clearly defined, all alternative methods are considered, and the system is confirmed to be fully de-energized. This includes shutting down and locking out all machinery and agitation or pumping equipment. The ventilation system must be inspected and functioning to ensure maximum airflow.

Key pre-entry steps include identifying structural and atmospheric hazards, verifying adequate ventilation, establishing clear communication between the entrant and an outside observer, and ensuring the observer is trained, properly equipped, and remains outside the pit at all times. A written entry permit or checklist must be completed to confirm that all safety measures are in place.

Confined Space Safety: Manure Storage Flyer

Dimesions: 8.5×11

A flyer/handout version of the Confined Space Safety: Manure Storage Poster. This flyer can be used in the field when discussing safety in and around manure storage with agricultural workers. It can also be used in the classroom as a teaching aid, summarizing key points for safe entry into manure storage areas.

Additional Resources on Confined Space Safety

Ag Health 101

Unit 6. Confined Spaces

This section of the Ag Health 101 course focuses on different hazards associated with entry and work in confined spaces. We define what this means, identify common spaces on the farm, and present best practices for key confined spaces, including grain bins and manure storage units.

Information from Unit 6. Confined Spaces was used to create the posters, “Confined Space Safety: Grain Storage Structures” and “Confined Space Safety: Manure Storage” (above). Listen to the audio chapters from Unit 6 of Ag Health 101, or view the Unit Summary pages on Confined Spaces, for more information on this topic.

Print Materials: Air Quality & Gas Exposures

Air Quality & Gas Exposures Poster

Dimensions: 11×17

This poster presents a detailed overview of air quality hazards in livestock and grain production, categorizing them by source and type. In livestock environments, significant risks include methane and ammonia emissions from manure handling systems such as slatted floors, lagoons, pits, and tanks—especially when manure is foaming—along with gases produced by animals and combustion byproducts from gas-fired heaters. Grain production hazards include toxic gas emissions from out-of-condition grain, gas-fired dryers, overheating equipment, and silos containing fermenting silage, which can produce dangerous gases like carbon monoxide, nitrogen dioxide, carbon dioxide, and hydrogen sulfide.

Beyond gases, the poster also highlights non-gas hazards such as dust, endotoxins, animal handling risks, and the dangers of grain engulfment and dust explosions. Health impacts from these exposures range from eye and lung irritation to paralysis, respiratory damage, reduced mental function, and death. To mitigate these risks, the poster stresses the importance of properly using and maintaining gas monitors and refers to a FarmSafe podcast episode for further guidance. The message underscores the need for proactive safety practices in managing air quality hazards across agricultural operations.

Air Quality & Gas Exposures Flyer

Dimesions: 8.5×11

A flyer/handout version of the Air Quality & Gas Exposures Poster. This flyer can be used in the field when discussing gas sources in livestock production and grain bins, and the associated hazards with agricultural workers. It can also be used in the classroom as a teaching aid, helping students visualize which gas sources in agriculture are associated with which hazardous exposures.

Additional Resources on Air Quality & Gas Exposures on Farms

Ag Health 101

Unit 5. Air Quality & Gas Exposures on the Farm

This section of the Ag Health 101 course focuses on different airborne contaminants that are generated by farming operations.

Information from Unit 5. Air Quality & Gas Exposures on the Farm was used to create the poster, “Air Quality & Gas Exposures” (above). Listen to the audio chapters from Unit 5 of Ag Health 101, or view the Unit Summary pages on Air Quality & Gas Exposures, for more information on this topic.

Print Materials: Gas Monitors

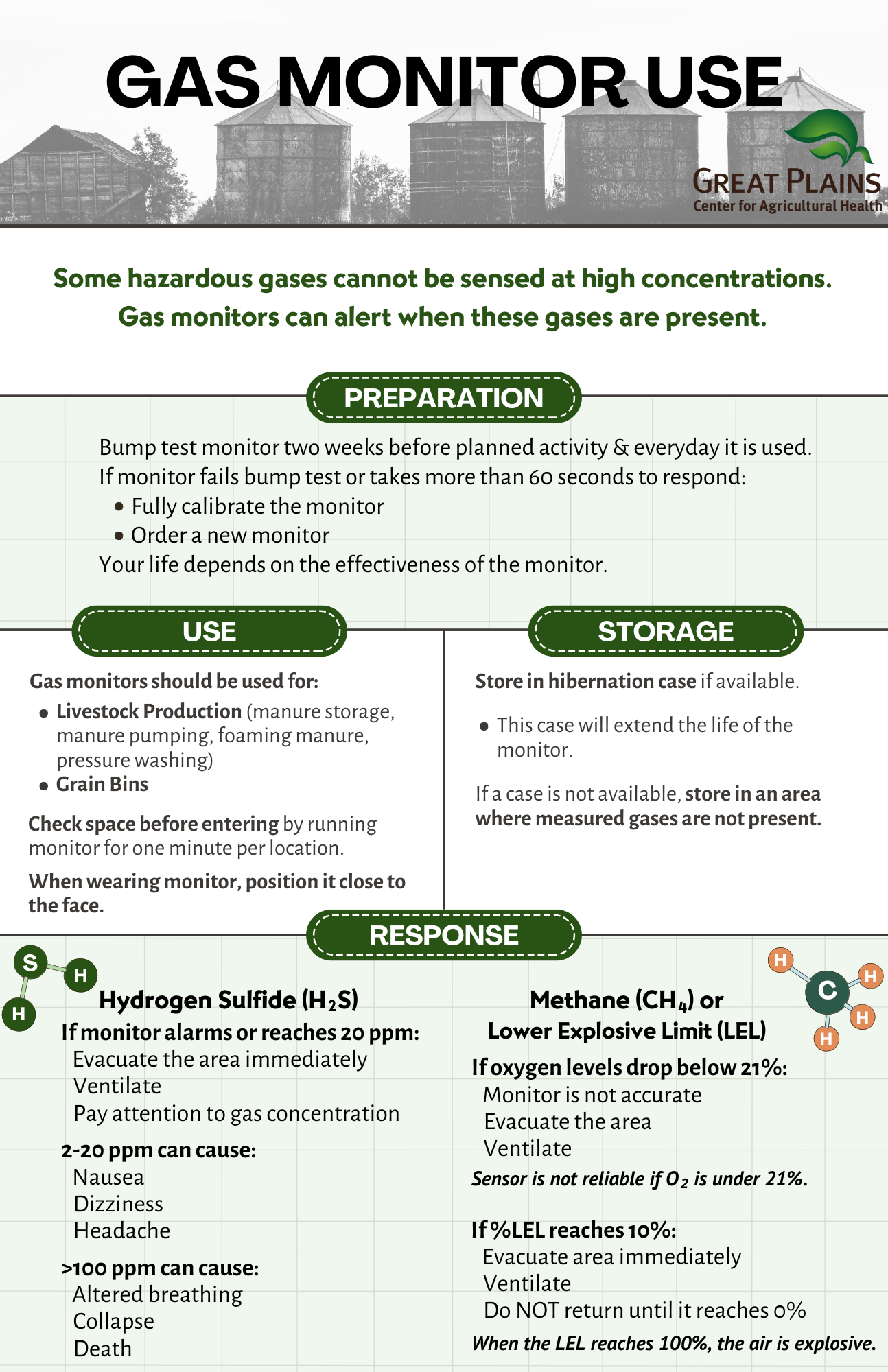

Gas Monitor Use Poster

Dimensions: 11×17

There are some operations on the farm that generate hazardous gases in high concentrations, and some of these exposures have caused farmers and family members to die. Simple, low-cost gas monitors are available to identify these unknown hazards and save a life. This poster highlights how to select, maintain, and use these monitors and summarizes what the concentrations mean.

Additional Resources on Gas Monitors

FarmSafe Podcast

S1E22 | Gas Monitors

In this episode, we continue our conversation about manure gas hazards. The focus today is on gas monitors that can be used to detect the presence of hydrogen sulfide and methane. Because we cannot sense the presence of hydrogen sulfide or methane at high concentrations, we need to rely on a gas monitor to detect and alert us when we are in danger. Renee Anthony, an industrial hygienist, talks about how to use, store, and bump test these monitors.

“Having a monitor that is giving you those numbers, gives you that additional amount of decision-making ability– it’s like this is really dangerous, I’m going to go out, absolutely nobody’s going to go in, we’ve got to ventilate for a little bit longer, figure out what’s going on and then we’ll recheck the area.”