PERSONAL PROTECTIVE EQUIPMENT (PPE) RESOURCES FOR THE FARM

Before performing tasks on the farm, it is important to “take 5” minutes to reflect on the hazards that might be present and determine if any personal protective equipment (PPE) would help reduce these risks if worn. In industrial operations, the employer is required to perform a PPE Hazard Assessment to determine whether and which PPE is necessary to perform a task safely and make sure everyone knows what PPE to use and why. Safe farms can apply these same techniques to prevent injury and illness from exposures that could be prevented with the adoption of appropriate and well-fitting PPE.

This web page identifies some common hazards on the farm that should be assessed when evaluating hazards for a job and then identifies categories of PPE to consider. After understanding these hazards, we will walk through common PPE used on the farm as we recommend how to protect a farm worker from head to toe from hazards associated with a task. This section discusses selection considerations, certification to look for in devices, and additional resources available to help understand how to select, use, and maintain this equipment.

Page Topics

Click on a topic below to jump to that PPE section on this page.

EXAMPLE FARMING HAZARDS & RECOMMENDED PPE CATEGORIES TO CONSIDER

When conducting a PPE hazard assessment for a specific task, it is important to consider the need to protect multiple parts of your body to determine if exposures present a hazard that could adversely affect you anywhere from your head to your toes. This process is outlined, in this order, below.

When evaluating hazards on the farm, it is important to match the hazard to PPE to wear. It may be helpful to realize this level of hazards before we proceed in selecting protection for a specific task, which often involves multiple hazards from the list below (and others!). Here are some common hazards to consider when determining PPE needs.

Dusts: This category includes small particles that may be from organic materials, bacteria, endotoxin, fungal spores, or dust with pesticide residues.

-

- Whenever tasks generate airborne concentrations of dust, we need to consider its composition and how it may interact with the eyes, respiratory system, and skin.

- Eye protection should be selected based on whether dusts are moving with speed (impact hazard) or settling in the air.

- Respiratory protection for dust ranges from simple filtering facepiece respirators (“N95s”) to full-facepiece respirators, depending on the inhalation hazard of the dust.

- Coveralls may be sufficient to prevent clothing contamination of some hazardous dusts.

Chemicals: This category includes pesticides, liquid fertilizers, gasoline, diesel, and hydraulic fluid. It also includes pharmaceutical medications for your animals.

-

- To understand the hazards of a particular chemical you are handling, it is critical to review the manufacturer’s safety data sheet. Look at both Section 8 (Exposure controls/PPE) and Section 4 (First aid measures) for a quick idea of the hazards and protection recommendations.

- For pesticide use, break out your glasses and look at the recommendation on the label as well as the safety data sheet.

- Look for protection recommendations on the safety data sheets, but also understand how the chemical is going to be used to determine the level of protection needed. Protection will differ when handling concentrated chemicals compared to diluted ones, but pouring versus spraying would result in different exposure types (splash to eyes and skin from pouring versus inhaling fine aerosolized particles from spraying), resulting in different types of protection needed.

- Depending on the task, you might need eye protection, respiratory protection, chemical protective gloves, and clothing, maybe including shoes.

Compressed gases: This category includes items such as liquid propane (LPG) and welding gas cylinders.

-

- Eyewear is often suggested when conducting tasks where gases could be released. Some gases may need protective gloves.

- Propane, for example, can cause frostbite if contacts the skin. Thus, gloves need to be chemical resistant and provide suitable cold protection when “filling cylinders” from a storage tank.

Confined spaces: These include grain bins, manure storage structures, and silos.

-

- If you don’t know whether there is sufficient oxygen or whether concentrations of gases in the space are dangerous (e.g., you don’t have a gas monitor), entry using a supplied air respirator is the only safe entry.

- These spaces may also have physical hazards and depending on what is in the space and how entry/exit conditions are, a retractable lifeline and safety harness are likely needed for the entrant.

Potential projectiles: This includes dust and other byproducts from cutting, grinding, sawing, drilling, and mowing.

-

- Eye and face protection is important to prevent impact of solid particles that can damage the eyes and skin.

- When cutting trees, for example, the cutting device (chainsaw) introduces additional hazards, that may suggest additional protection needs to be worn because of the hazard of the blade itself: leg and foot protection are recommended as well as eye/face protection when using a chainsaw.

Sound levels: The rule of thumb is that when you are in environments that make you raise your voice to be heard, the sound level may be approaching or in hazardous range, resulting in reduced hearing loss over time.

-

- Sound commonly in this range is generated by machinery, livestock, tools

- Hearing protection, either muffs or plugs, is commonly used to minimize the risk of hearing loss from a lifetime of exposure to noises from agricultural operations

Sun: When working outside, protection from the sun is needed to reduce the likelihood of developing skin cancer, and the selection of clothing can reduce the likelihood of overheating in hot weather.

-

- Sun-blocking lotions, clothing, hats, and glasses

- Breathable fabric to wick away sweat

Working at Heights: A personal fall arrest system is recommended when working 6 feet above ground level.

Working Below Others or in Tight Spaces: Consider the risk of anything falling from above or hitting your head on anything.

-

- Head protection includes a hard hat, safety helmet, or bump cap, each of which has different performance characteristics.

Information on guidance to select PPE to use for pesticides is summarized in this motion graphic: https://youtu.be/ePDXNt3yITQ?si=NUrhDfMAwaqQuAqu

PROTECT YOURSELF FROM YOUR HEAD TO YOUR TOES

When conducting a PPE hazard assessment for a specific task, it is important to consider the need to protect multiple parts of your body to determine if exposures present a hazard that could adversely affect you anywhere from your head to your toes. This process is outlined, in this order, below.

Head Protection

If there is overhead work (where something might fall onto someone’s head below) or if you are working in areas where the risk of hitting your head (such as on equipment, beams, or piping), head protection is recommended. A hard hat or a newer safety helmet (a hard hat that has a chin strap) that is used must comply with ANSI Z89.1. There are two types (Type 1 for impact from the top; Type 2 for impact from above or the side) and different electrical classes for electrical hazards: a Class G protects up to 2000 volts, but utility workers need a Class E hard hat. It is rare to use a hard hat on a farm, so only select this as “required” if there truly is an overhead hazard that requires protection.

Other hazards to the head, such as sun exposure, may suggest requiring a hat (the bigger the brim the better) to reduce the risk of overheating and the likelihood of skin cancer.

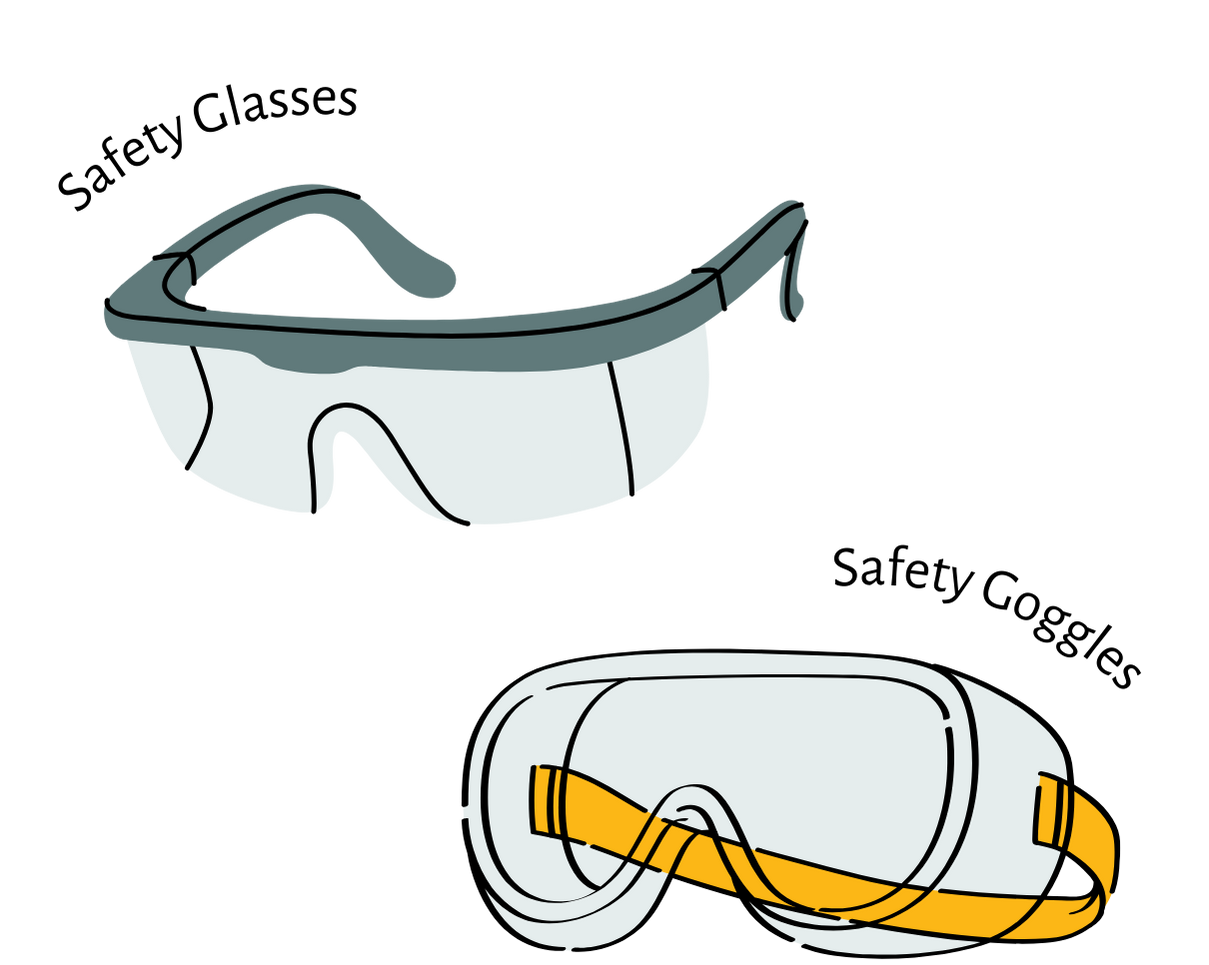

Eye Protection

There are two main categories of eye protection, and selecting the appropriate one requires understanding the hazard that requires protection. It is important to note that standard prescription glasses may not be sufficient to withstand impaction. Eyeglass stores do have prescription eyewear that meets ANSI Z87 criteria, which needs to include both the frame and the lens. These often have “clip-on” side shields to expand the protection of these prescription glasses.

-

- Safety glasses protect the eyes from flying objects, with lenses and frames tested to withstand the impact of a ½” steel ball moving at 150 f/sec. ANSI Z87 is the basic safety class standard that eyeglasses must comply with, so look for this on the packaging/when purchasing.

- Safety goggles are suggested to provide improved protection for smaller fragments (like when grinding) compared to safety glasses because these goggles seal the eye. Goggles come in vented (for non-chemical hazards) or non-vented (if chemicals are part of the hazard) styles. If chemical splashes are possible, safety goggles are recommended over safety glasses.

- Welding lenses are also needed when welding on the farm. There are relatively inexpensive auto-darkening lenses that dim as soon as the welding arc is struck, but older welders may have fixed lenses that require the selection of lens shade number by knowing the type of welding, electrode size, and arc current. See this table or this table.

Hearing Protection

When working in loud areas, even for short durations, hearing protection is recommended. Most people know about both earmuffs and earplugs, which are available at most hardware and farm stores. The goal of hearing protection is to reduce the sound level at the ear (inside the ear of the wearer) to below 85 dBA. Visit our page here for specifics on hearing protection use, selection, and guidance.

Hand and Arm Protection

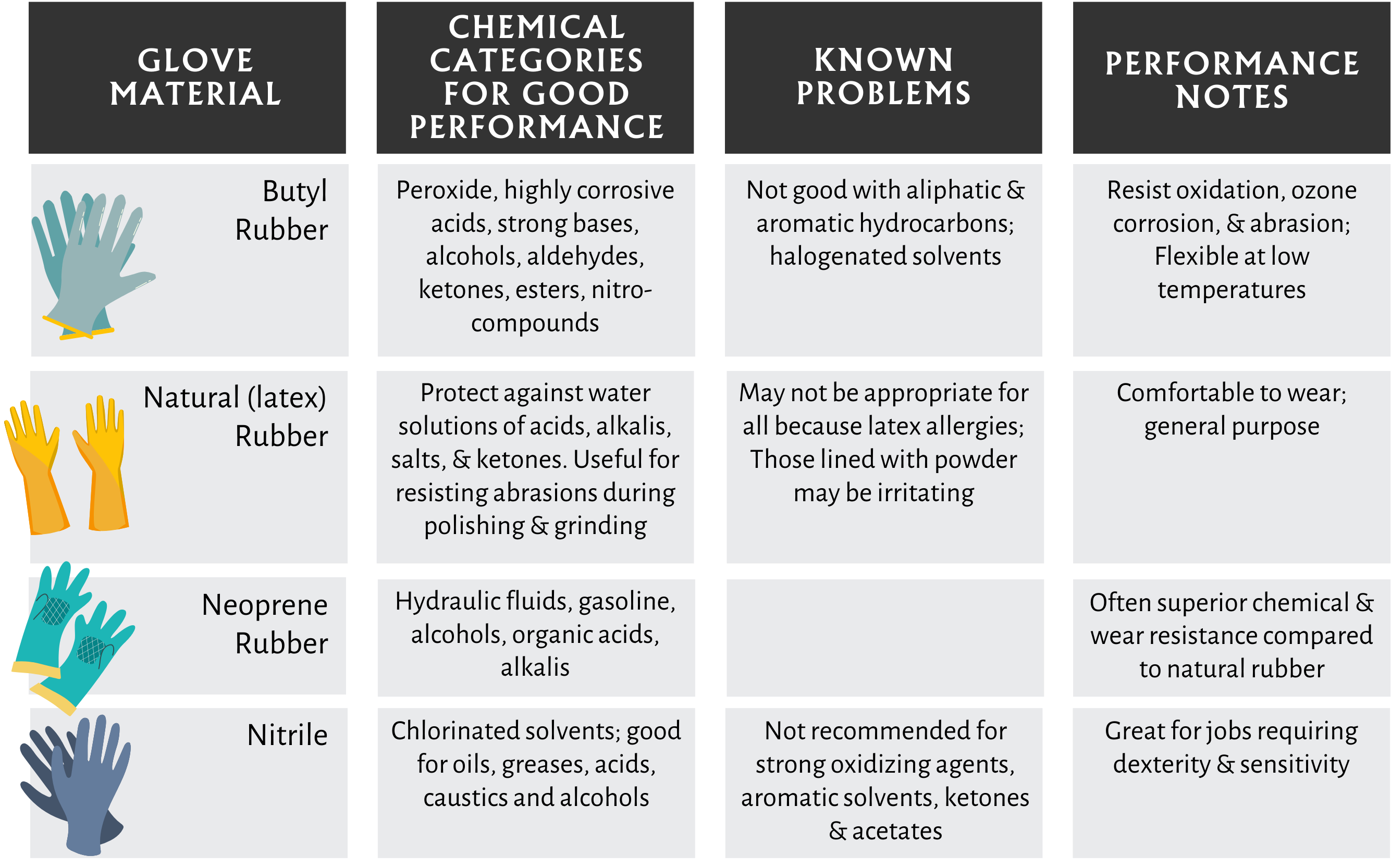

There is no ANSI standard for gloves like there are for eye and face protection. When selecting gloves, it is important to understand the protection needed (physical abrasion, chemical protection) before selecting the right materials for use. There are four main groups of gloves:

-

- Work gloves made of leather, canvas, or metal mesh (not for chemical protection; mostly for heat or cut resistance)

- Fabric and coated fabric gloves (again, not for chemical protection; mostly for dirt and slip-resistant protection)

- Chemical- and liquid-resistant gloves (if chemical protection is needed)

- Insulating rubber gloves (for electrical hazards)

The following need to be known to select the glove material for chemical-resistant gloves:

-

- What is the chemical being handled? Review the Safety Data Sheet, particularly Section 1 for identification and Section 8 for PPE recommendations.

- What is the nature of contact? Will you have to contact the chemical to do the job, or are you protecting against splashes? Low likelihood of contact means we can use gloves that do not have to withstand hours of exposure, so long as we rinse or replace gloves that contact the chemical.

- How long does the contact occur? If tasks are short-term, you may want cheap disposable materials. If tasks take a longer time, you may need more durable materials, particularly for chemical and abrasion hazards.

- How much more than just the hand needs protection? Do you just need the hand, or the hand and forearm, or do you need full arm protection? Again, the answer to this question requires knowledge of the task being performed.

- What is the worker’s grip requirement? Will the hand be mostly dry, or will it be wet or covered in oil? A super thick glove will make it difficult to have a strong grip or do tasks requiring fine dexterity. It is good to test out sample gloves for tasks to make sure grip is not sacrificed, which could lead to more hazardous situations (dropping chemicals, e.g.)

- Do you need thermal protection? Remember, for dispensing liquid propane, we need thermal protection.

- What size and is it comfortable? Always recommend trying out gloves to check fit and comfort. Insights from others who conduct this task are also needed. There are standard glove size calculators to help select sizes, such as here.

- Does any of the tasks required when wearing a glove have abrasion as a risk? If so, determine which materials seem better than others for abrasion. For example, nitrile is better at not tearing compared to latex: although a box of nitrile gloves costs a bit more per box than latex, people find nitrile more pleasing to wear and are more durable during many tasks, so long as the glove fits well.

The table below provides a general description of glove materials that are available on the market which will help you perform a first assessment of chemical resistance for the glove with chemicals it is being used for. It is critical to confirm the chemical resistance for YOUR chemical with the GLOVE MANUFACTURER’s Data for the glove you purchase. This table gives you a general place to start the selection process.

Table 1: General Glove Performance Information

See Table 4 in https://www.osha.gov/sites/default/files/publications/osha3151.pdf for chemical-specific chemical resistance selection guidance for these four glove families, but then check with your glove manufacturer to confirm with their formulation.

For a motion graphic showing you a brief explanation of chemical glove use and care, please visit: https://youtu.be/XO5V94Sx4c8?si=K7MqywCtduDsvcdw

Body Protection

There are some tasks that require protecting the body from additional hazards, including physical hazards (temperature, tools) and chemical hazards. Selecting the material and body coverage needed based on the hazard that needs protection. Body protection can include coveralls, vests, jackets, aprons, or full-body suits. Here are some guidelines for material types:

Paper-Type Fiber

Paper-type fiber, including Tyvek, is for single-use protection against dust and possible splashes (remove if splash occurs).

Treated Wool or Cotton

Treated wool and cotton is comfortable in a wide range of temperatures and are fire-resistant, protecting against abrasions and rough irritating surfaces.

Duck Cloth

Duck cloth is heavier than above and protects against cuts and bruises when handling heavy or sharp/rough materials.

Leather

Leather is used to protect against dry heat, flames, and sparks.

Rubber or Neoprene

Rubber, rubberized fabrics, neoprene, etc. protect against chemical hazards. The same recommendations to check the fabric with the chemical of concern with the manufacturer is recommended.

Personal Fall Protection System

When working at heights, including any work inside a grain bin with any stored materials inside, a personal fall protection system is needed. This system requires the person at risk of falling to wear equipment (harness, a lanyard that connects to the harness and an anchor point) and the structure to have sufficient anchorage (5000-pound force) to support the force of a falling worker and to successfully retrieve the person who may be engulfed. On the farm, these systems are recommended for roof work, working at elevation, and when entering grain bins and manure pits.

Foot and Leg Protection

Additional foot/leg protection can include:

-

- Snap-on leggings to protect from heat hazards from welding sparks

- Metatarsal guards to protect the instep from impact and compression hazards

- Foot + shin guards to protect the lower legs

- Puncture-resistant insoles

- Electrically conductive soles (never wear if exposed to electrical hazards)

- Oil-resistant soles

- Electrical hazards shoes (prevent the wearer from completing an electrical circuit to the ground)

Respiratory Protection

Respirators should be selected based on the airborne hazard facing a worker. To select the correct respirator, we need to know the hazard (what is the gas, vapor, dust), the concentration of the hazard in the environment, and the “safe level” of that contaminant, called the “Occupational Exposure Limit” or OEL.

Respirator Cartridge Color Coding

Respirator Selection

From that information, you can determine the type of respirator based on how each of the following questions are answered:

-

- Is there sufficient oxygen (19.5%) in the environment? To use an air-purifying respirator, there MUST be sufficient oxygen to breathe.

- Is the concentration of the contaminant below the manufacturer’s maximum use concentration (MUC) of a respirator-cartridge combination? The respirator can be used safely only if the concentration in the air is LOWER than the manufacturer’s MUC.

- If below the MUC, you select the simplest type of respirator based on whether it provides enough protection. To do this, calculate the Concentration / Assigned Protection Factors (set by OSHA) for the respirator you want to use. If this ratio is below the OEL, you can use that TYPE of respirator.

The Assigned Protection Factor (APF) based on the respirator type

-

-

- Half mask and face-filtering = 10

- Powered air-purifying respirator (PAPR) = 25,

- Full face air purifying respirator = 50;

- Supplied air respirator= 1000+ (https://www.osha.gov/sites/default/files/publications/3352-APF-respirators.pdf)

-

Only NIOSH-certified respirators can be used in the US to protect workers from airborne hazards. Here is a respirator selection guide.

Additional Respirator Resources

Additional information to help you determine what you need and how to take care of it is provided in these resources:

-

- Common respirator types and how they work page from the Ag Health and Safety Alliance

- How to care for your respirator motion graphic

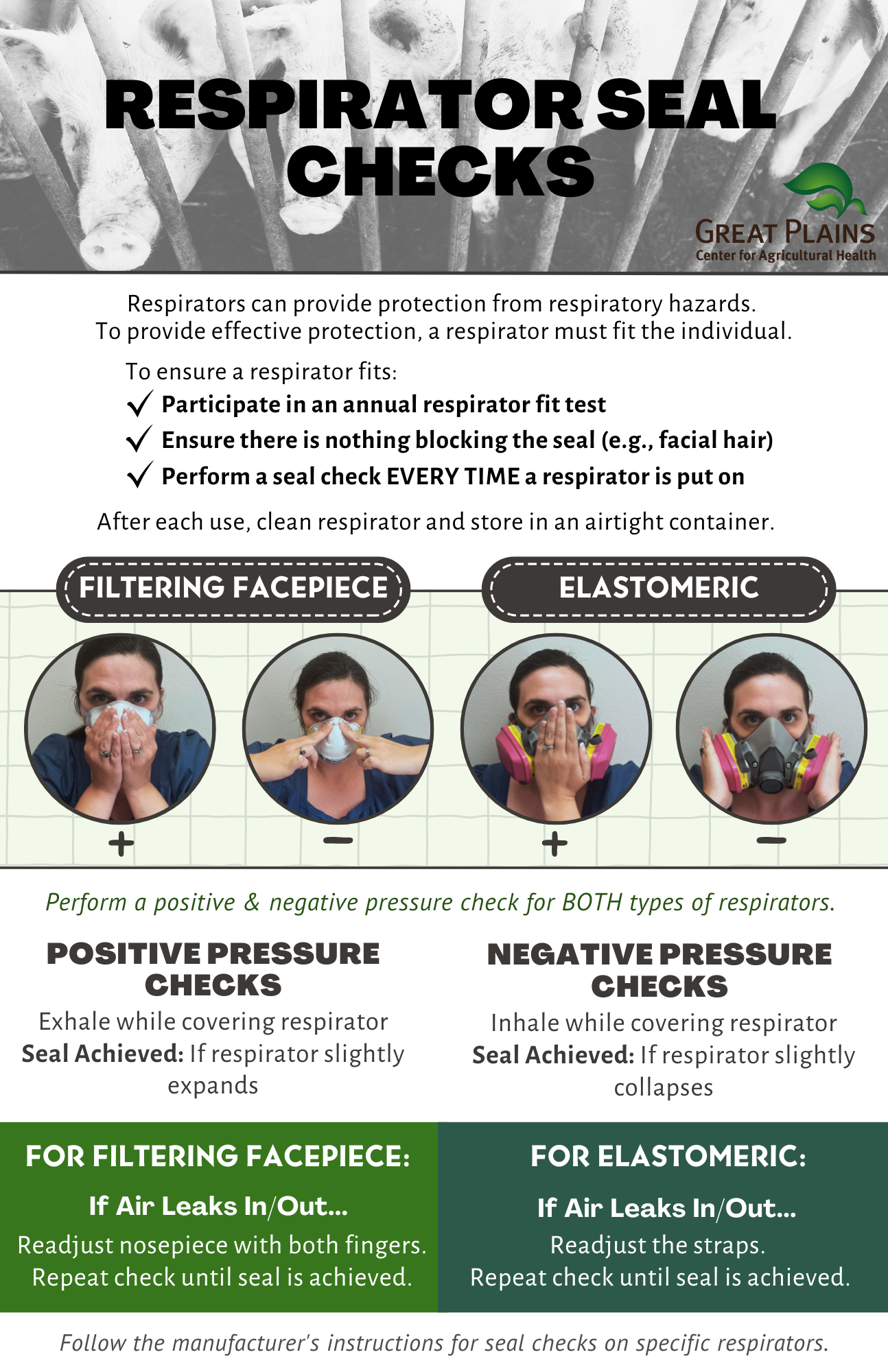

- Respirator Seal Check poster

- Respirator Fit Test Guide is a train the trainer guide that shows people how to conduct fit testing, to make sure the respirator fits the face of the wearer.

This guide is an example of how the concentration and hazard levels determine respiratory protection while working with poultry during avian influenza outbreaks.

PRINT RESOURCES

To take our introductory audible course on PPE from Ag Health 101, visit Unit 7: PPE.

To learn about interactive tools to help demonstrate PPE selection and facilitate conversations with others about PPE on the farm, visit Meet the Flat Farmers.

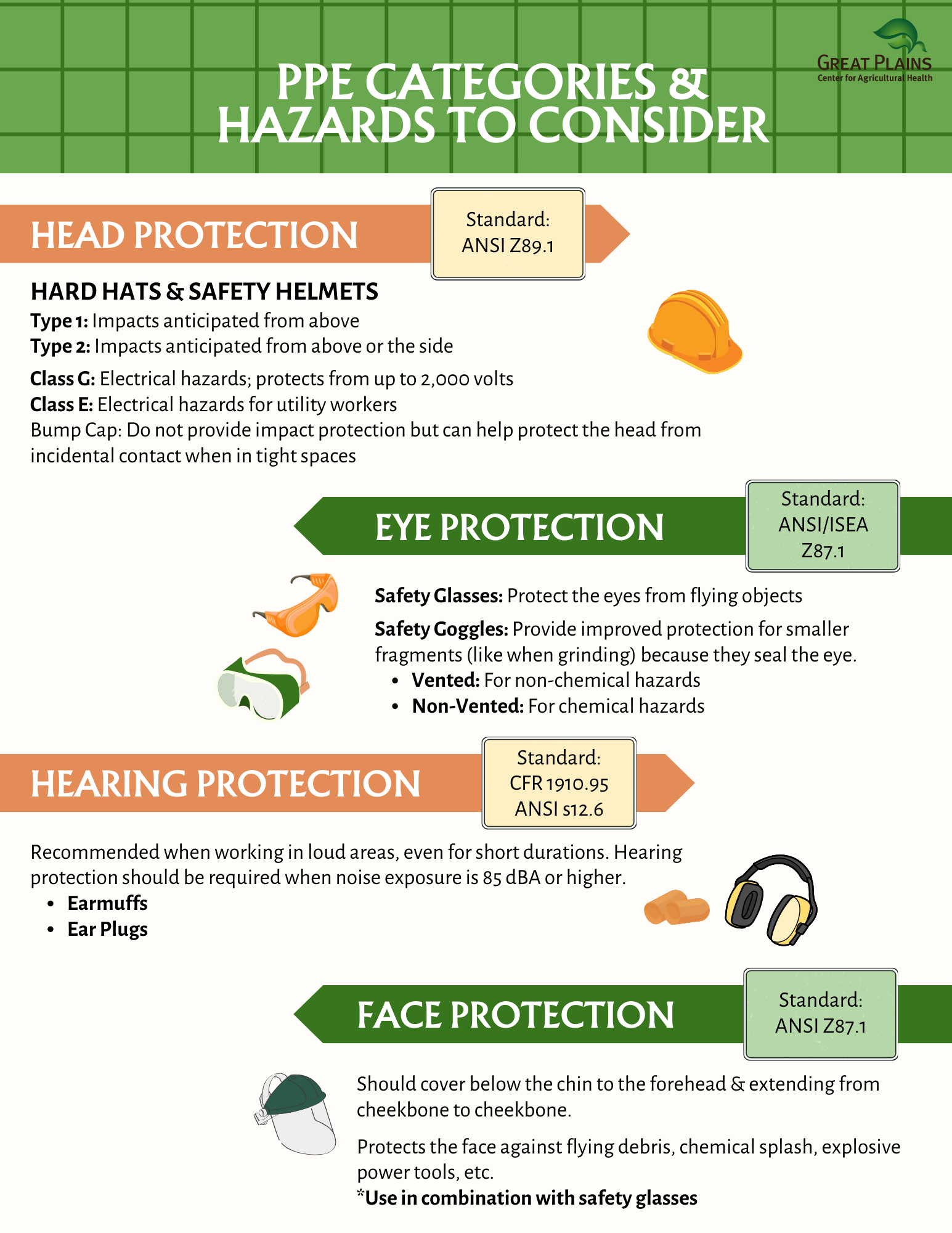

Download this printable Rack Card that summarizes the PPE Categories discussed on this page along with the hazards to consider.

This poster offers comprehensive guidance on selecting the correct respirator for agricultural workers, emphasizing the importance of matching respiratory protection to specific hazards and work environments. It distinguishes between air-purifying respirators and supplied-air respirators, outlining when each type is appropriate.

This poster identifies the simple procedure to follow every time you put on a respirator. It shows how to do this with the filtering facepiece respirator (the “N95”) and with an elastomeric respirator.